Less Friction

Reduce Adhesion

Increase Ease of Cleaning

Solve your production process problems with

our Micro Dimple Process

What is Micro Dimple Process?

Micro Dimple Process is a surface treatment with many potential benefits.

The effects that arise from making surfaces “easy to slide” offer a variety of benefits in many areas, such as in food, Cosmetics and pharmaceutical manufacturing.

Increased Production Efficiency

Improves performance of hoppers and sieves

Hoppers are often used to shuttle flower through processing lines for bread, confections, noodles and other baked products. Common issues are clogging by the powders, yield loss and difficult cleaning processes and excessive noise from knockers.

With our Micro Dimple Process the hopper requires only half the slope angle of an untreated hopper for the powder to slide. Sieves require approximately half the amount of time to sieve product through.

Our Micro dimple process reduces the adhesion of powders and improves the sliding of packaging. It can also reduce the sticking of moist and sticky foods such as meats and doughs. By treating the inner surface of equipment such as kneaders and mixers, food loss can be prevented. Our surface treatment also makes it much easier to clean the surfaces with only water. Less downtime equals more profit.

Suppresses Adhesion

Prevents food loss and reduces time required for cleaning.

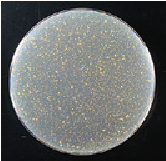

Inhibits Bacterial, Viral and Fungal Growth

Less Wear and No Foreign Contamination

Treatment process with high durability

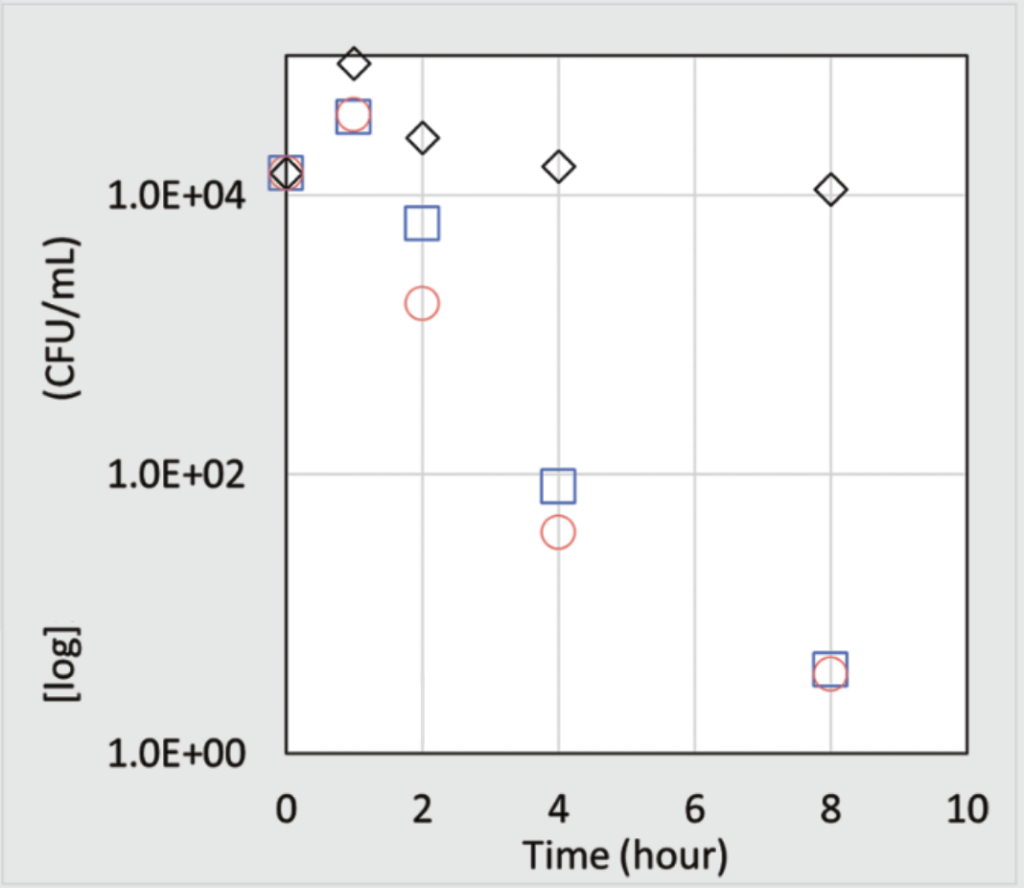

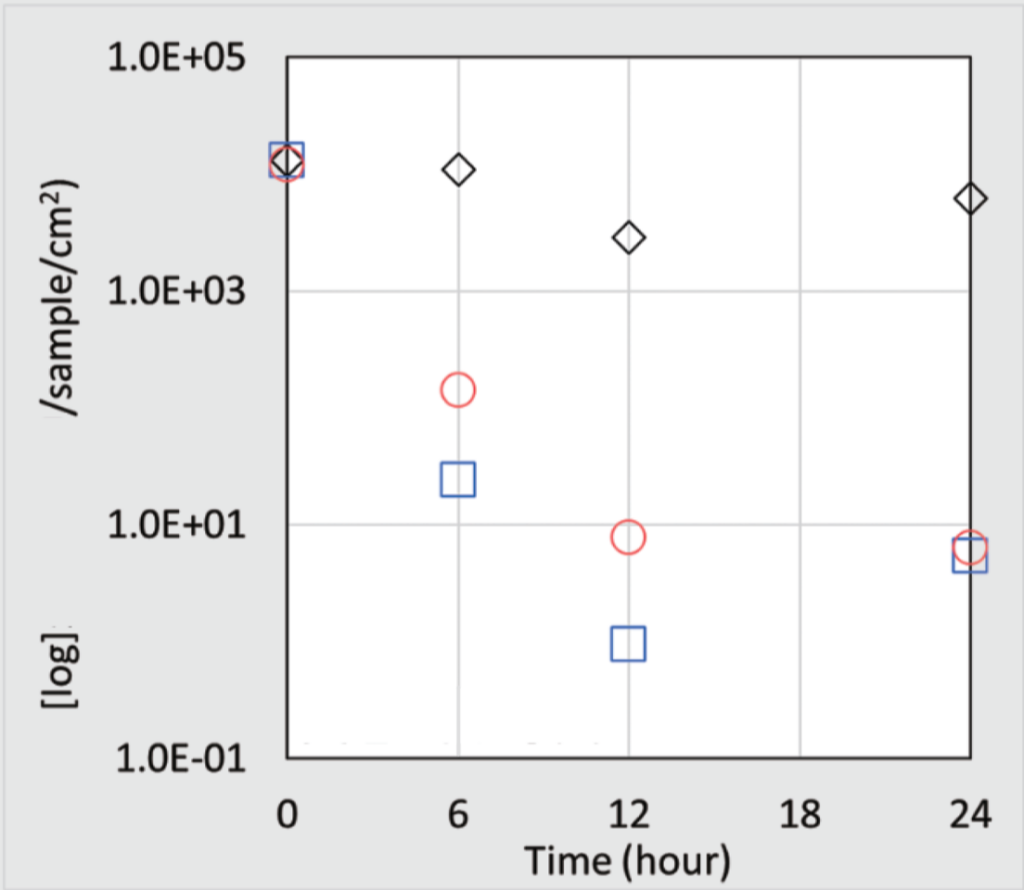

Antibacterial Properties

Studies have shown that uneven surfaces inhibit the movement and growth of common bacteria. Our process isn’t a coating, therefore improves hygiene.

Wear Resistance

This process hardens stainless steel surface by about twice as much over untreated and increases it’s overall wear resistance.

Prevents Contamination

Unlike a coating, our Micro Dimple Process is a surface treatment so there is ZERO contamination due to peeling of coating films over time.

Applications

- Food Industry

- Cosmetic Industry

- PHARMACEUTICAL INDUSTRY

Food Industry

Customer Issue:

Having trouble with powder clogging. Excessive knocker noise. Food spillage and blockage of the production line.

Although the machinery is embossed, it is difficult to wash because food waste accumulates in the concave area.

If the powder adheres to the magnet, the iron powder cannot be removed and clogging occurs.

I’m using a tapping ball, but I’m worried that the debris will become a cause of foreign matter contamination.

I want to treat a pipe that takes time and effort to remove. I also want an antibacterial effect.

Liquid drips from the nozzle when filling curry sauce, dressing, etc.

Cosmetics Industry

The sieve net clogs up quickly due to the high oil content of the foundation.

When molding pressed foundation, a lot of it adheres to the pestle, which makes the next molding messy.

Lipstick molds are difficult to release, resulting in cosmetic imperfections.

Cosmetic bottles do not slide well and fall over during transportation.

When facial cleansing powder is mixed and dispensed, a large amount of powder remains in the mixer, resulting in a low yield.

Pharmaceutical Industry

The sieve net becomes clogged due to the large amount of fine powder chemicals.

Weighing errors occur when medicine is left in the trough.

When eye drops are filled into an eye-drop container, the liquid continues to leak out from the nozzle, resulting in a weight error.